Maze

Maze

Stanford Product Realization Lab, 2019

front view of the maze. The main body has a bead blasted finish, while the dogs have their original machined finish from the CNC for contrast.

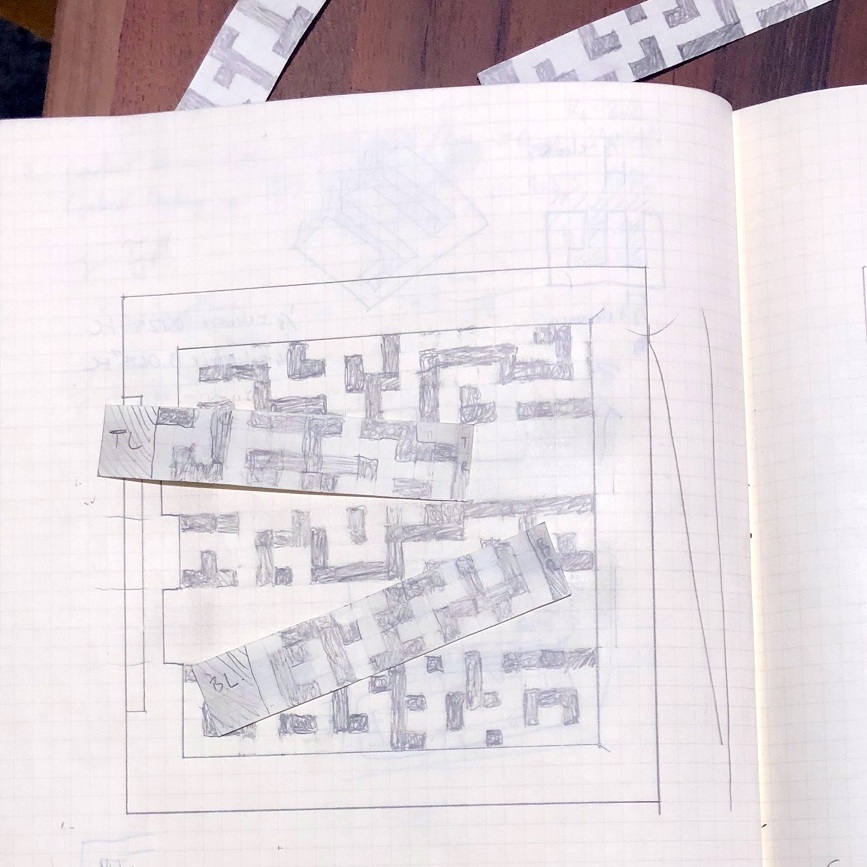

As an introduction to CNC machining in Computer Aided Product Realization (ME 318) at Stanford, I was challenged to quickly design and machine a maze using provided stock material and tooling. My maze contains two sliding dogs that can be adjusted by pulling pins located outside of the maze. In order to make it to the finish, players must pull the dogs back and forth to explore and open up new paths. Once the player reaches the end, a one-way channel allows for the ball to quickly return to the start for the next play through.

For this project I sought to create a maze that was dynamic and unique. Creating components that moved into different positions made for a novel puzzle-solving element which I found fun to design around. Thinking up different ways to leverage the moving components as part of the maze puzzle was one of my favorite parts of this project.

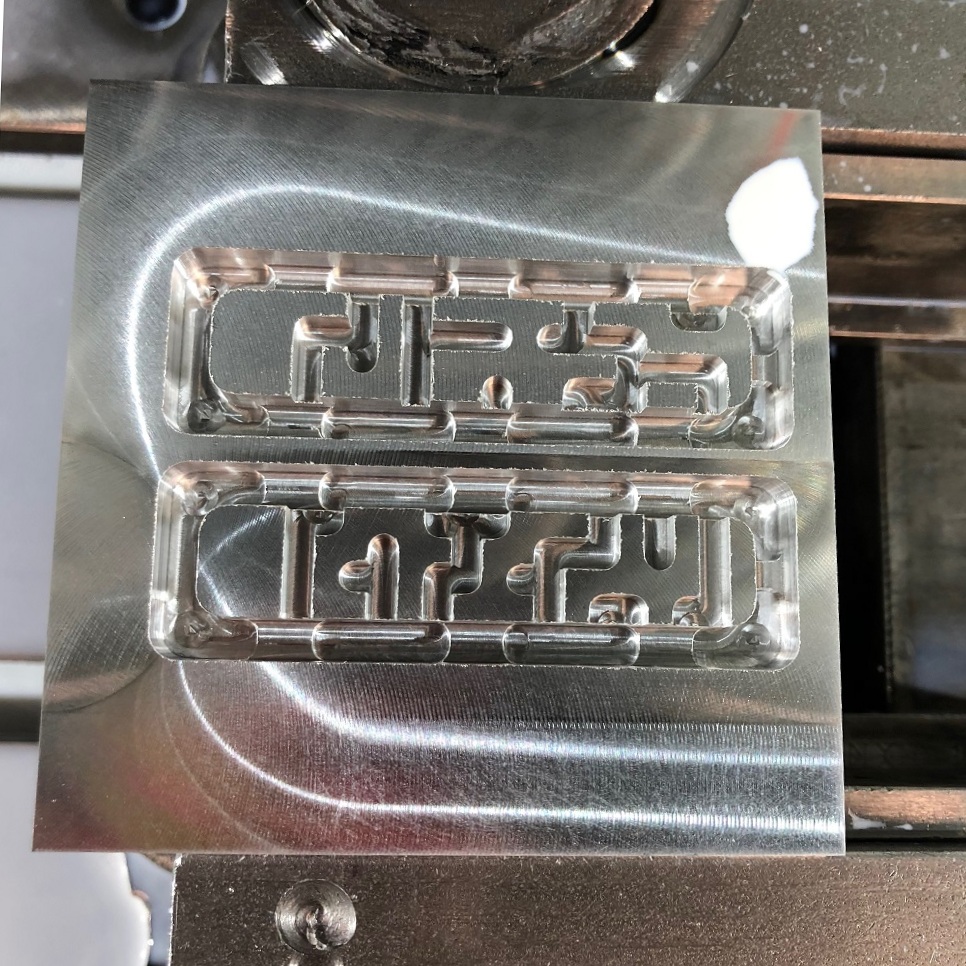

The main body of the maze was machined in one operation on a Haas VF2, and the dogs were machined out of a separate piece of stock using tab features. Once out of the CNC, the tabs were removed on the band saw and then milled down on a manual mill. The pins were turned using round bar stock on a lathe. Although creating custom pins was extra work, I wanted to maximize real estate in the maze, and so by designing and turning them myself I was able to minimize their footprint.

The pull-tab mechanisms feature a small T-slot that the pins lock onto. The pins are threaded on the ends, and two small nuts are tightened on the end to create the retaining feature. To install, the pins are inserted into a through hole on the side of the maze. A spring is installed onto the pin, and then the nuts are threaded onto the end and tightened against each other. The T-slot is machined onto the backside of the dogs of the maze. The acrylic case holds the dogs down in the pocket, preventing them from sliding off the pin.

Since the maze was designed to be played in one direction— from start to finish— I included a channel that features a small acrylic flipper to help the ball return to the starting point quickly. I originally planned to make this part out of bent sheet metal, but when I laser cut the top cover of the maze, I included a quick test part and was satisfied with the results, and so I kept it.